描述

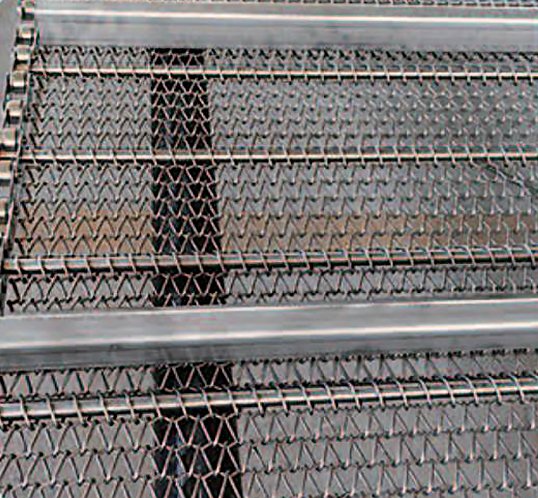

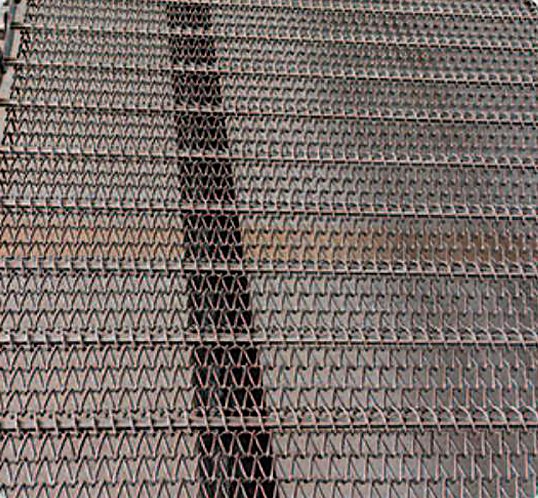

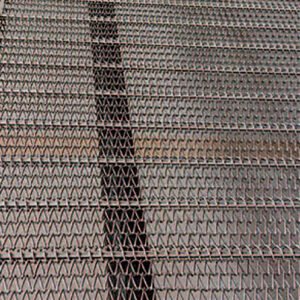

The service life of sintering furnace mesh belt.Sintering furnace mesh belt is a type of high-temperature mesh belt,usually made of SUS314 material that is resistant to high temperatures.Here are some key production points:

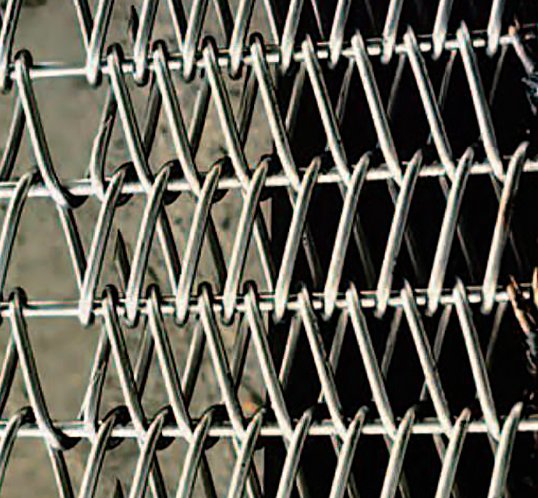

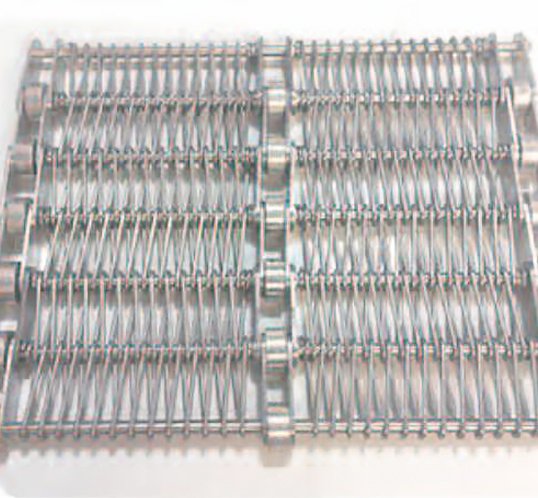

Twisted edge hooking process:The use of twisted edge hooking process on the edge of the mesh belt can make the edge of the mesh belt more secure and less prone to damage.A curved hook is an extension of a thread that twists one edge into another, commonly known as a hook.This can improve the load-bearing capacity of the mesh belt.

Consistency of thickness:When making mesh belts,it is necessary to ensure that the horizontal thickness of the mesh belt and the hook is consistent,so that the mesh belt can run smoothly in the furnace and avoid damage to the mesh belt.

Material selection:The sintering furnace mesh belt is generally made of high-temperature resistant SUS314,2080,and Nippon Steel SUS314 materials.These materials have good heat resistance and corosion resistance,which can effectively extend the service life of the sintering furnace mesh belt.

The main characteristics of metal heat treatment mesh belt are:

1.High temperature resistance:Metal heat-treated mesh belts are usually made of high-temperature resistant metal materials, such as SUS310S stainless steel,Cr2ONi80 nickel chromium alloy,Inconel601,etc.These materials can maintain stable performance in extreme high temperature environments with a temperature resistance range of up to 1200℃ .

2.High strength and low elongation:At high temperatures,metal heat-treated mesh belts can maintain high mechanical strength and low elongation,ensuring that they are not easily deformed or damaged in high-temperature environments.

3.Good oxidation resistance and corrosion resistance:These materials have good oxidation resistance and corrosion resistance,and can perform well in high-temperature oxidation environments,extending their service life.

4.Customized services:According to different process requirement。

Reviews

There are no reviews yet.